We offer a wide line of surgical sutures that meet the highest quality standards, as well as the requirements of health institutions, contributing to the success of all types of surgical procedures.

We are a company specialized in the production and distribution of sutures, surgical needles and medical devices for periodic replacement. Our suture plant is recognized globally for the quality of its products, as well as the application and development of technology in its manufacturing; an unprecedented feat in the region.

Our unwavering interest in improving the efficiency in the manufacturing of surgical sutures, surgical needles and medical devices for use in surgical interventions, respiratory emergencies, low-temperature sterilization and other specialties, leads us to work under the premise of continuous improvement and innovation.

Along the same lines, we comply with the requirements of Good Manufacturing Practices and the international quality standards of ISO 9001 and ISO 13485, which has also led us to obtain FDA Cleared authorization to market our absorbable surgical sutures in the North American market.

Advanced conventional and reverse tapered cutting needle edges for easy initial penetration.

Excellent needle that retains the curvature of the needle during application.

Homogeneous suture needle surfaces for minimal tissue damage.

Specially processed suture needles for high fixation strength.

Micro-tapered spatula with conventional and reverse cutting edges for minimal penetration.

Needle with ultra-smooth surface for less tissue trauma.

Special process for needle fixing.

Optimal needle cutting edges for drag-free passage through the toughest fabric.

Microconical needle for minimal penetration force.

Special suture needle fixation process for maximum strength.

Excellent suture and knot tensile strength.

Very smooth surface, which produces minimal tissue trauma.

Maintains tensile strength, perfect for suspension procedures.

Ultra-sharp needle point for atraumatic tissue penetration.

Silicone coated needle for smooth passage of tissue.

This material addresses the need for a softer, more absorbable synthetic suture. It also passes through tissue easily and with minimal resistance.

Polyglactin sutures facilitate easy handling, as they have a smooth knot glide and unmatched knot security. In addition, the suture is composed of a copolymer of lactide and glucoside (polyglactin 910), coated in equal parts with polyglactin 370 and calcium stearate.

After two weeks of implantation, approximately 79% of the tensile strength of the polyglactin suture is maintained. Approximately 58% of the tensile strength is retained after three weeks for sizes 6-0 and larger. At three weeks, 57% of the tensile strength is retained for sizes 7-0 and smaller. After four weeks, 25% of the original strength is retained for sizes 6-0 and larger. However, all of the original strength is lost by the fifth week postimplantation.

Polyglactin exhibits minimal absorption by hydrolysis up to 40 days and almost complete absorption between 56 and 70 days. Lactic and glucoside acids are readily eliminated from the body, primarily in urine. Like uncoated sutures, polyglactin sutures elicit only a mild tissue reaction during absorption. However, their safety and effectiveness in neuronal and cardiovascular tissues have not been established. In addition, transcutaneous or conjunctival sutures left in place longer than seven days may cause localized irritation and should be removed as indicated. Polyglactin sutures are also available in violet-dyed braided strands and undyed natural strands in a variety of lengths, with or without needles.

The polyester monofilament composite, poly(p-dioxanone), represents a significant advancement in suture options. It combines the features of a soft, flexible monofilament construction with the ability to be absorbable, providing prolonged wound support for up to six weeks. Additionally, it causes only a mild tissue reaction, making this material suitable for many types of soft tissue approaches, including pediatric cardiovascular, orthopedic, gynecologic, ophthalmic, plastic, digestive, and colonic surgeries.

Like other synthetic absorbable sutures, polydioxanone sutures are absorbed by hydrolysis. Approximately 90% of the tensile strength is maintained after two weeks of implantation, 90% at four weeks, and 62% after six weeks. Absorption is minimal until approximately postoperative day 90 and is essentially complete within six months. However, the safety and effectiveness of polydioxanone sutures in microsurgery, neural tissue, and cardiovascular tissue in adults have not been established. Polydioxanone sutures are available in violet and purple strands to enhance visibility.

This monofilament suture is characterized by superior flexibility, which makes it easy to handle and tie. Composed of a copolymer of glucoside and epsilon caprolactone, it is virtually inert in tissue and absorbs in a predictable manner. The surgeon may choose poliglecaprone sutures for procedures requiring high initial tensile strength that decreases over the two postoperative weeks. This includes subcuticular closure, soft tissue approximations and ligations, with the exception of neural, cardiovascular, ophthalmic and microsurgical applications. Additionally, poliglecaprone sutures are available in dyed (violet) and undyed (natural) versions.

Dyed poliglecaprone suture retains approximately 60% to 70% of its original strength at seven days post-implantation. This is reduced to 30% to 40% after fourteen days, with all original strength lost by 28 days. On the other hand, undyed poliglecaprone suture retains approximately 50% to 60% of its original strength at seven days, and about 20% to 30% after fourteen days post-implantation. Finally, all original tensile strength of undyed poliglecaprone suture is lost by twenty-one days post-implantation. Absorption is essentially complete by 91 to 119 days.

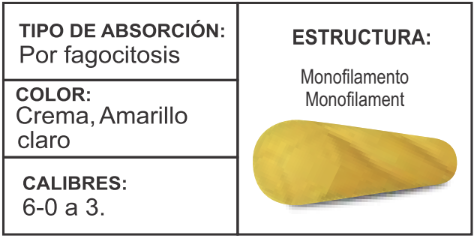

Chromic gut is treated with a chromium salt solution to resist the body’s enzymes, extending absorption time for over 90 days.

Chromic catgut sutures minimize tissue irritation, causing less reaction than plain surgical catgut during the early stages of wound healing. Tensile strength can be maintained for 10 to 14 days, with some measurable strength remaining for up to 21 days.

Plain catgut is rapidly absorbed. Moreover, tensile strength is maintained for only 7 to 10 days after implantation. Absorption is complete within 70 days.

The surgeon may choose to use plain catgut on tissues that heal quickly and require minimal support; for example, to ligate superficial blood vessels and suture subcutaneous fatty tissue. In addition, plain surgical catgut may be subjected to a special heat treatment to accelerate strength loss and absorption.

This rapidly absorbed surgical catgut is primarily used for epidermal suturing, where the sutures are only needed for five to seven days. However, these sutures have less tensile strength than similarly sized plain surgical catgut according to USP. Finally, rapidly absorbed plain catgut should not be used internally.

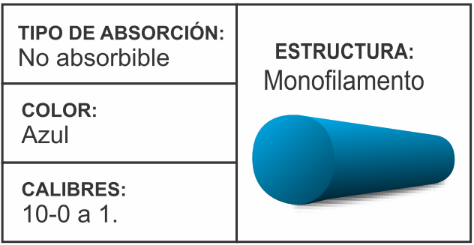

These sutures are extruded in monofilament strands or non-

capillary single strands, characterized by high tensile strength and extremely low tissue reactivity. However, they degrade at a rate of approximately 15% to 20% per year by hydrolysis.

Nylon sutures in sizes 10-0 and 6-0 and larger are produced from a special grade of nylon 6. Additionally, medical grade nylon 6-6 is used for sizes 7-0 and finer. While both grades allow for good handling, monofilament nylon sutures tend to return to their original, straight, extruded state (a property known as “memory”).

Therefore, more knot ties are required to secure monofilament sutures compared to braided nylon sutures. In addition, monofilament nylon in moist or wet conditions is more flexible and easier to handle than in a dry state. Also, a limited line of nylon sutures (sizes 3-0 to 6-0) are pre-moistened or “flexed” for use in cosmetic plastic surgery. This process improves the handling and knot tying characteristics to resemble braided sutures.

Nylon sutures are frequently used in ophthalmic and microsurgical procedures in very fine sizes. For this reason, sizes 9-0 and 10-0 have an intensified black tint for increased visibility.

For many surgeons, surgical silk represents the standard of

handling performance against which new synthetic materials are compared, especially

because of its superior handling characteristics. Silk filaments can

be twisted or braided, with the latter process providing the best

handling qualities. Silk for most suture sizes, prior to the

braiding process, allows for a tighter, more compact braid, which

significantly improves suture quality. After braiding, the strands are dyed,

cleaned and stretched, and then impregnated and coated with a wax or

silicone mixture.

Each of these steps is critical to the quality of the final suture and must

be performed in a precise order. Surgical silk is often dyed black to

improve visibility in tissue. Raw silk is graded for strength, uniformity in filament diameter, and freedom from defects. Only the highest grades of silk filaments

are used to produce silk surgical sutures. However, surgical silk loses tensile strength when exposed to moisture and must be used in a dry state. Although silk is classified by the U.S.P. as a non-absorbable suture, long-term studies in living subjects have shown that it loses most or all of its tensile strength in approximately one year and is usually undetectable in tissue after two years.

Therefore, it actually behaves like a very slow-absorbing suture.

Widely used in general, cardiovascular, plastic and orthopedic surgery, polypropylene sutures do not adhere to tissue and are therefore efficient as removal sutures. Polypropylene sutures are relatively biologically inert, offering proven strength, reliability and versatility.

Therefore, polypropylene sutures are recommended when minimal suture reaction is desired, such as in contaminated and infected wounds, to minimize subsequent sinus formation and suture extrusion. They are available in clear or blue-dyed versions.

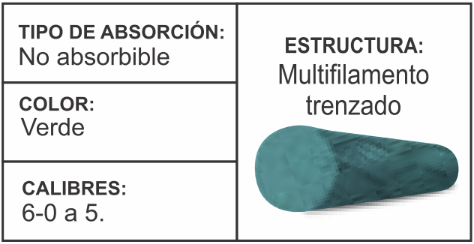

Polyester suture is braided and non-absorbable, composed of polyethylene terephthalate fiber.

Polyester sutures have excellent tensile strength and high quality braiding. They are not subject to degradation and maintain their tensile strength indefinitely in the body.

Polyester suture is a non-absorbable, braided and coated surgical suture.

Polyester sutures are available in USP sizes from size 5 to 2-0. Sutures are available in green, white and black.

Polyester sutures are used for permanent or removable fixations and in cardiovascular surgery.

– Dr. Jonathan Smith

Do you have any questions? Send us an email

Copyright © 2024 Suturex. All right reserved.